Neudorfer Engineers LLC, AN INTEGRA COMPANY

SERVICES WE PROVIDE

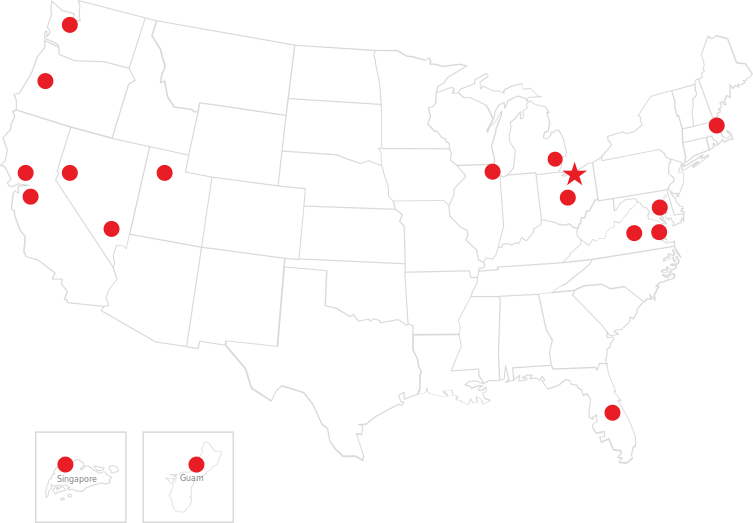

Neudorfer Engineers LLC is certified by the National Environmental Balancing Bureau (NEBB) and meets the needs of building owners and mechanical contractors worldwide.

Neudorfer Engineers’ team approach provides clients with a complete balancing, testing, and commissioning package that is economical for all types and sizes of buildings. Combination of these services benefits the building manager with increased operational efficiency, lower operating costs, and improved occupant comfort and productivity.

Years of Experience

Projects Completed

Countries

recent projects

Community Transit Casino Road

Commissioning and Testing, Adjusting, & Balancing (TAB) of approximately $8M project with 68,000 SF of renovated office, data center, auditorium, and support spaces.

Existing building interior was demolished and renovated. Select mechanical, electrical, and plumbing equipment was re-used. The building is a modernized office and operations facility for Community Transit. The building comprises of offices, conference rooms, focus rooms, breakroom, maintenance, support, and restrooms.

Testing, Adjusting, & Balancing (TAB) services per Washington state energy code (WSEC), NEBB TAB standards, including design review, submittal reviews, coordination meetings, TAB survey, TAB agenda submittal, incorporation of TAB activities into project schedule, observation of deficiencies, commissioning coordination and back check, and submission of TAB final report. Balanced air distribution systems included: variable volume air handling units, fan-powered series terminal boxes, squeeze boxes, computer room air conditioning air handlers, heat recovery exhaust, and dedicated exhaust systems. Balanced hydronic distribution systems included variable volume heating hot water to air handlers and terminal boxes. Neudorfer’s TAB team coordinated with contractors to fast track repairs, balancing damper installations, motorized actuator replacements, and pressure control system adjustments on existing and renovated systems to maintain project schedule, while providing comfortable work environments for building occupants, prolonging equipment life cycles, and improving system efficiencies.

Whole Building Commissioning (Cx) services per Washington state energy code (WSEC), NEBB Re-Cx standards. Commissioning design phase services included design review, Building Automation System (BAS) sequences of operations review, submittal reviews, coordination meetings, site visits, RFI coordination, incorporation of commissioning activities into overall project schedule, and writing Pre-Functional and Functional Test reports.

Commissioning construction phase and acceptance phase services included site visits throughout construction, witness of select equipment startup activities, review of contractor startup reports, back check of testing and balancing (TAB), and back check of BAS point-to-point verifications and calibrations. Issues were tracked via a single comprehensive issues log, reviewed with the project team during weekly project commissioning meetings, and tracked to completion.

Commissioning warranty phase services currently include review of training agendas, witness of Owner training, review of O&M manuals, submission of Cx final report. and diagnostics testing / review of trend reports after substantial completion.

Commissioned systems included:

- HVAC&R Central Plant Boiler

- HVAC&R Distribution (AHU’s, Terminal Units, Fans, AC’s)

- Witness of TAB back check

- Building Automation System (BAS),

- Lighting controls,

- Domestic hot water,

- Metering

P920 Bachelor Enlisted Quarters; Building Enclosure Testing and LEED Enhanced Commissioning

Building Enclosure Testing and LEED Enhanced Commissioning of a new 3-story, 75,000 SF military housing within Camp Lemonnier in Djibouti, Africa. P920 bachelor enlisted quarters included 126 residential units.

Whole Building Commissioning (Cx) services included BAS sequences of operations review, submittal reviews, coordination meetings, writing and execution of Pre-Functional and Functional test reports, back check of testing and balancing, and tracking of observed deficiencies into project deficiencies log until closure. Commissioning scope included installation verification and functional performance testing of new HVAC, Building Automation System (BAS), solar voltaic panels, domestic hot water, lighting controls, telecommunications, fire alarm, & security systems. Engineering duties included design and submittal review, value engineering, RFI coordination, budget control, scheduling, witness of Owner training, review of O&M manuals for incorporation into Systems Manual, review of building operations, and LEED 10-Month Review.

Building Enclosure Testing services per ASHRAE 0-2005, & the National Institute of Building Sciences (NIBS) Guideline 3-2012 requirements. BET services included design review, submittal reviews, coordination meetings, writing and execution of test plan, installation verification, blower door testing, & thermal imaging.

WSDOT I-90 Tunnels Two-Way Transit & HOV Operations Stage 3; Testing, Adjusting, & Balancing and Commissioning

Testing, Adjusting, & Balancing (TAB) and Commissioning (Cx) of site improvements to the existing Inter-state route I-90 eastbound & westbound roadways, bridge, Mercer Island tunnel, and Mount Baker tunnel in Seattle, WA. The two tunnels remained open to traffic with scheduled traffic closures during critical activities, cutovers, and tests. Within this section of interstate I-90, over 150,000 cars travel each day. Existing supervisory control and data acquisition SCADA systems were updated & centralized, including new programmable logic controllers (PLC) and human machine interface (HMI) devices.

Testing, Adjusting, & Balancing (TAB) of emergency egress fans and generator exhaust fans per Washington state energy code (WSEC) requirements and NEBB TAB standards, including design review, submittal reviews, coordination meetings, TAB surveys, TAB agenda submittals, incorporation of TAB activities into project schedule, observation of deficiencies, commissioning coordination and back check, and submission of TAB final reports per building. NEI TAB team coordinated with maintenance staff and contractors to fast track repairs, sheave changes, belt changes, motor replacements, and system adjustments on existing and renovated systems to maintain project schedule.

Commissioning services included design review, sequences of operations review, submittal reviews, coordination meetings, site visits, witnessing electrical equipment testing, witnessing mechanical equipment startups, writing and execution of Pre-Functional and Functional test reports, back check of testing and balancing, and tracking of observed deficiencies into project deficiencies log until closure. Engineering duties included RFI coordination, budget control, scheduling, witness of Owner training, and review of O&M manuals. Commissioning scope included installation verification and functional performance testing of site improvements to Electrical (Medium Voltage), Roadway Lighting, Roadway Signage, Roadway Fire Suppression & Alarm, Infrared Cameras, & Heat Fiber Cables, Roadway Drainage, Smoke Evacuation Fans (200,000 CFM), & Integration of SCADA, closed circuit television (CCTV), Fire Alarm, & Fire Suppression systems.

Does Your Building meet the new COVID-19 OSHA STANDARD?

if not, we can help.